Rocking Segment Mechanism (page 2)

The topics:

- tens carry,

- zero setting,

- the sum mechanism and

- printing negative numbers

this all again demonstrated on the Continental 9 and 9S

Tens Carry

On page one we saw how the adding took place. We saw that after all the number keys were pressed, the handle should be pulled and released. This turns the gears of the register, with the equivalent teeth of the pressed numbers. But what when 6 and 5 are added together? Beside the adding of the actual digit, the subsequent digit / gear must be incremented to. The mechanism which is solved this, is the so called "Tens carry mechanism" and it is build in, in the calculation unit.

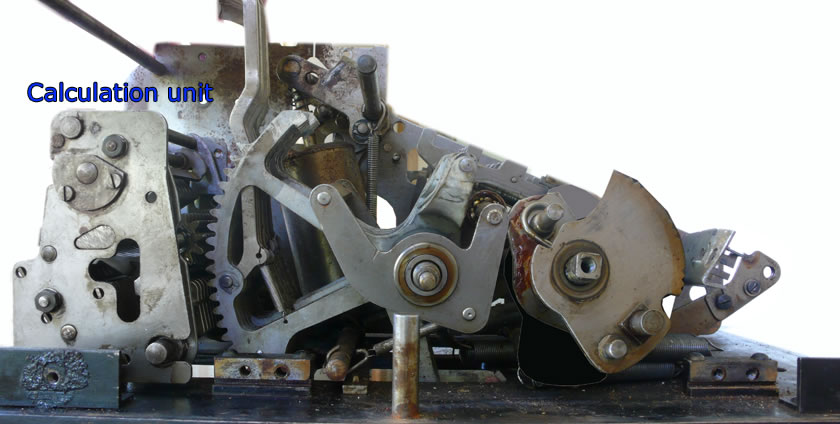

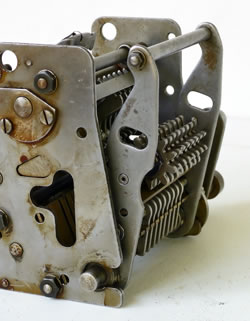

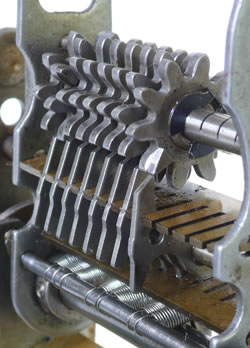

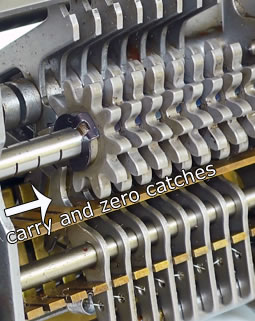

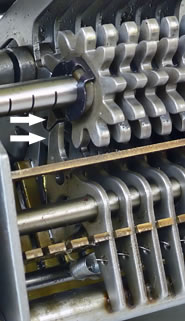

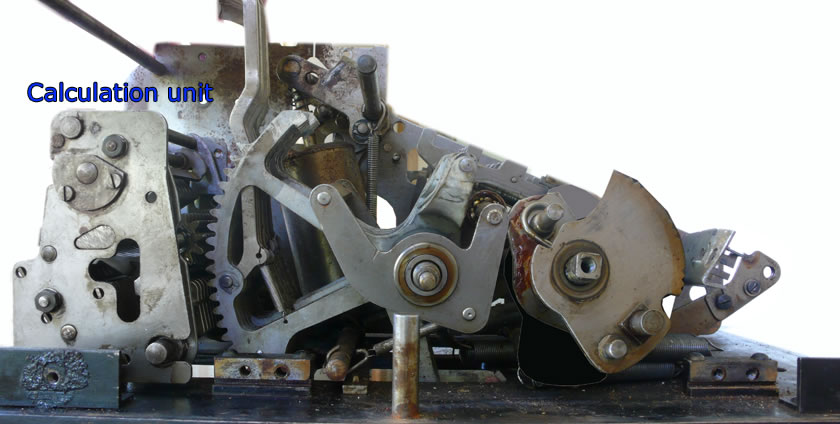

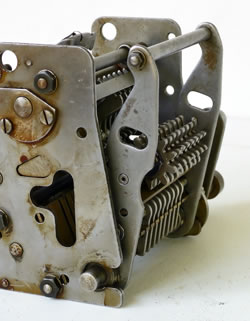

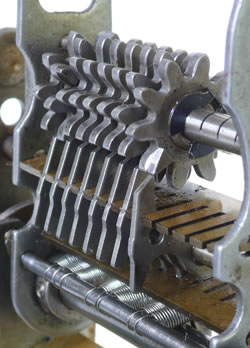

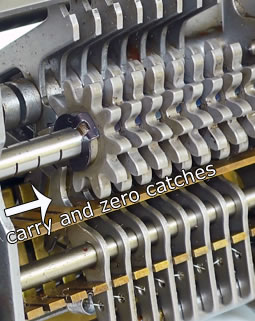

The calculation unit is separated from the machine on the three photo's above. The central part is the register, a gear row, here with 9 gears. This implies a calculation accuracy of 9 digits. And you see that the gear row is mounted in a hinged / turn able frame. The photo below to the left, is giving you a closer look on the gear row. The arrows point to the zero ridge. They are important for the tens carry and the zero setting. The mid and right photo below show the catches of those ridges.

And the ridges and the catches play a double role, they take part in the tens carry and the zero setting. The difference is that at the tens carry the gears are turning clockwise and at the zero setting they turn counterclockwise.

But first how does it works with the tens carry in more detail:

Starting with the position seen on the photo left above, when it will be updated by the segment. During that, the gear turns clockwise. When a gear is passing the nine to ten update (actualy zero), the ridge will push the catch away. Seen on the photo to the right below. (This is an photo taken from the inside of the calculating unit.) You see that the catch is pushed to the left and down.

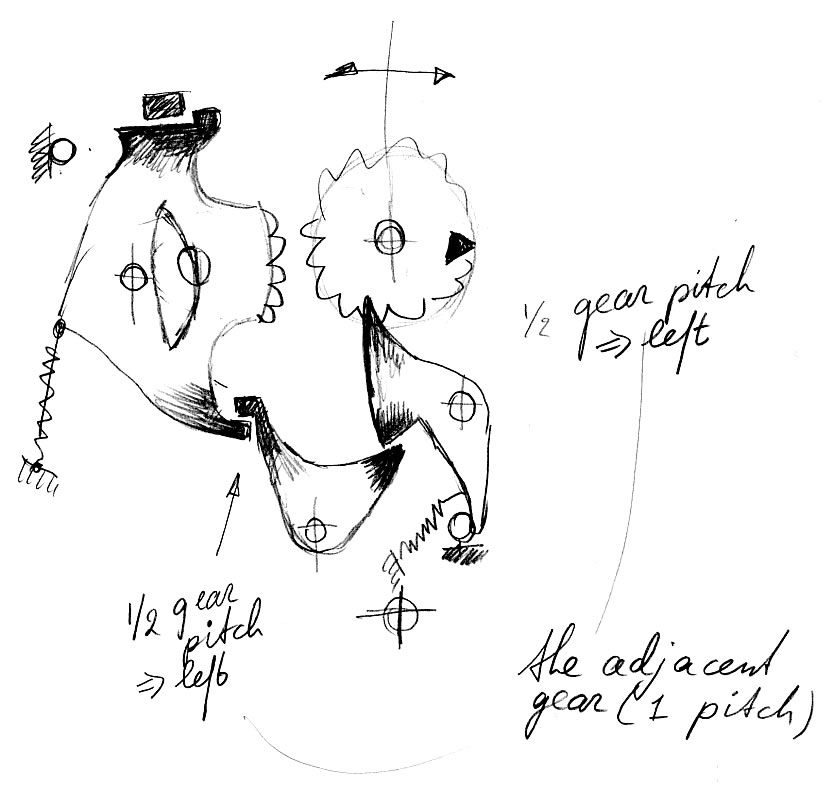

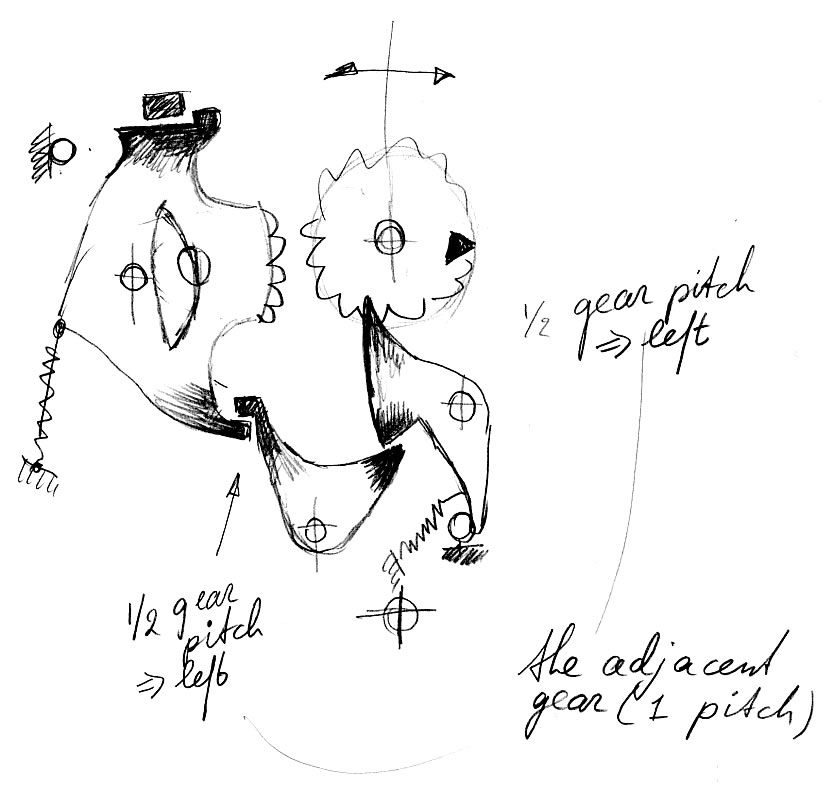

That will activate an other catch, which you can see on the photo left below. Here seen from the unit inside. In the middle of the photo you will find those, in the brass rack. These catches have two parts. When the lower part is pushed down the upper part will be released and pushed up. This upper part is a segment of teeth. (see the hand drawing below)

During this all, we have shift the full pitch towards the next gear position. (to the left, on the photo's ). So when that upper part is pushed up the gear of the next position will turn exactly one tooth up.

But this is not immediately done. The gearbox is outside after all, updated by the large segment. Therefore it is holding the carry update by the bar above, seen on the mid photo below (see the red marked teeth and the bar above). When the rod, above there, is pushing against the highest plate, the bar is releasing the upper part of the catch and the two red marked gears are turning one tooth, seen the photo on the right below.

These gears are increased by one, the ten carry is executed!!

Now the zero setting. After a total sum printing, the register is set to zero again. The photo's below showing this situation. After printing, the large segment is turning the gearbox, counterclockwise. This will stop when the ridge meets the catch. From this side the catch is not pushed away, see the shape of the catch. (Remember the photo to the left is taken from the inside.) When all the gears are set in this way, the gear box is put in the house / pulled off from the large segment, and stays, like the photo to the right below, shows.

The zero setting is executed !!

Printing intermediate & total sum

This procedure is not the same for every machine. We start with a machine who has only add possibilities. Like the machine above.

First we press the total sum key. When we pull the handle, the register gears are put on the segments first. The segments have in this sequence maximum freedom to turn the register gear. This turning freedom end when the zero ridge reach the zero catches. So each segment is turn back and stops at the zero ridge of the register.

In more computer terms you might say: "The register is read out". This is exactly what we want to print the total value.

When the handle is at its maximum position / deflection, the print head values represent the values of the register and the printing will occur. After that we will release the handle slowly and the gears are taken from the segments so that they will remain in their zero position. At that moment the print heads shoot to their maximum position and will follow the handle to the rest position.

When the intermediate / medial sum is pressed, nearly the same procedure

will be carried out. When the handle is released, after it reached his max, the gear is not taken of of the segment, but will remain there. So when the handle is released the gears will stay on the segment until just before the handle is at the rest position, so the gears will take their original value / position.

Subtracting

Later machines have subtracting possibilities as well. The used mechanism is very simple but clever.

A bit of theory. When we subtract 1 from ten, we get nine. When we subtract 1 from zero we like to get -1. But in terms of the gears we get 9. This notation is called the "nine compliment". But to get the preferred notation, we need a different subtracting mechanism. We do that by putting a second register on to the original register. When the register is turning, the second register is turning the opposite direction.

When we subtract a number below zero, the second register is punt on the segment and will turn the register backwards. Subtracting is performed. The two pictures below show the two registers in the two positions. (below and above zero results)

Printing Negative numbers

When the total result is below zero, for instance -13, printing is giving 999987, the nine complement notation, when the machine is not equipped with the special second register. When the machine is equipped with the special second register, the format is as we expected 13 -. The Minus sign is set when the register is passing the zero.

This is a personal hand drawing, explaining the mechanism in a more artistic way. Here you see the releases of the various catches stages more in a principal way. The comments are: "two times a half pitch shift towards the left adjacent gear".