The Rocking Segment or Oscillating Rack technology, is very appropriate for and widely used in adding and listing calculators. That made machines with this technology very attractive for small businesses. There are many machines build with- and various implementations of this technology. The "segment" or part of the circle gear (red), for instance differs. Some have even a toothed rack.

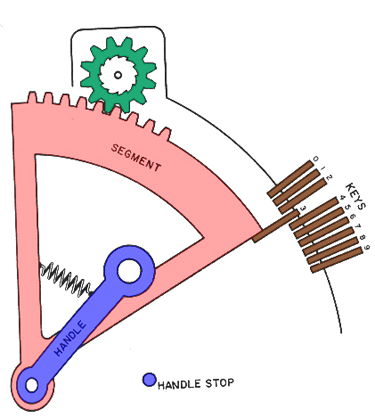

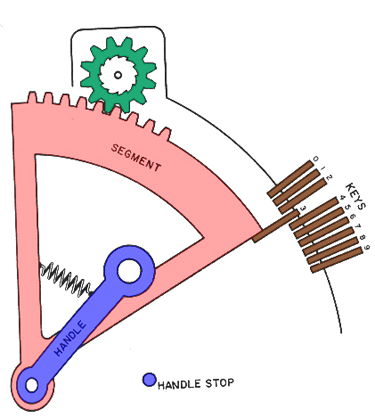

But the basic principle is the same for all. Let me explain it, on the basis of an adding of the figure 3: (please see the drawing to the left)

We start by pressing the key three and continue with a handle pull. This will turn the gear segment until it stops against the pin of pressed key three.

The handle is pulled further to its handle stop point. The green pinion gear is then put on the gear segment. The handle is slowly releasing again and the green pinion turns three teeth.

When the handle is coming to its rest position again, the green pinion is pulled off from the segment and is then locked for unwanted turning. This pinion gear is often called the "Register".

Remark:

This is a schematic drawing of this technology. At the drawing you see a zero key. The first machines are equipped with the so called full keyboards. A matrix of keys. You won't find the zero key's there and that's for a reason. In case a zero key was present, all leading and last zero's had to pressed. To prevent us from this needless work, a smart solution is invented: Make the zero key default.

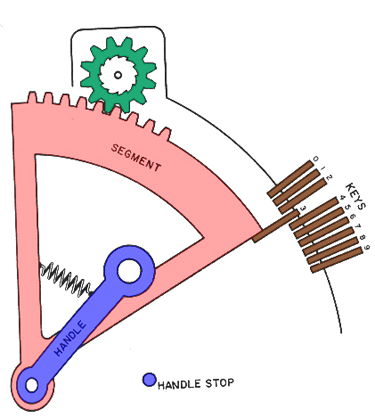

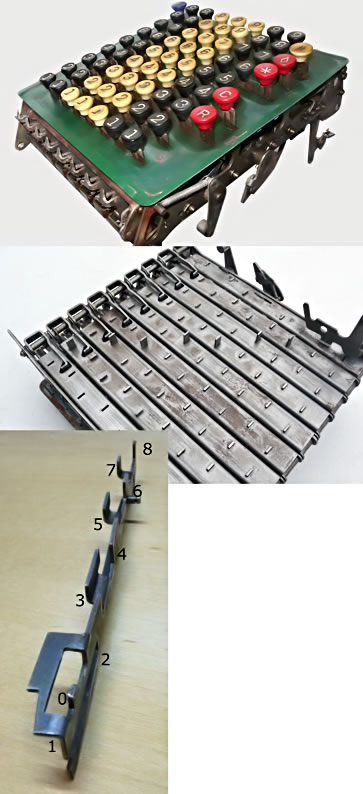

The separated keyboard is shown on the photo here to the left. The middle photo shows it bottom up, with the pins stacked out, corresponding the pressed keys. And the third photo left is showing one of the rocked plates.

A close look to these plates, which are located under each digit of the keyboard, shows two rows. The numbers at the rocks correspond with the pressed keys. Two rows, with alternated numbers, this to gain accuracy. It results in more distance difference, between each key, which is nice for the more precise conversion of the distance to the segments turn of tooth.

You probably have noticed that the nine is missing. This can be explained with help of the photo's below.

How does

it work?

When

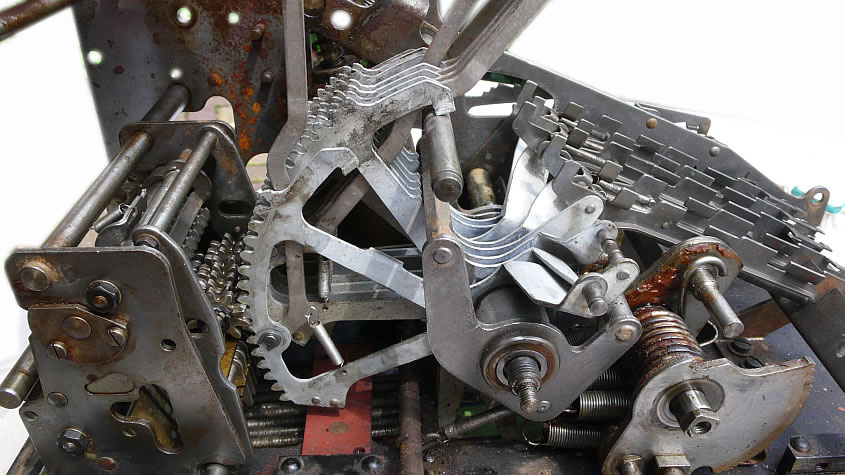

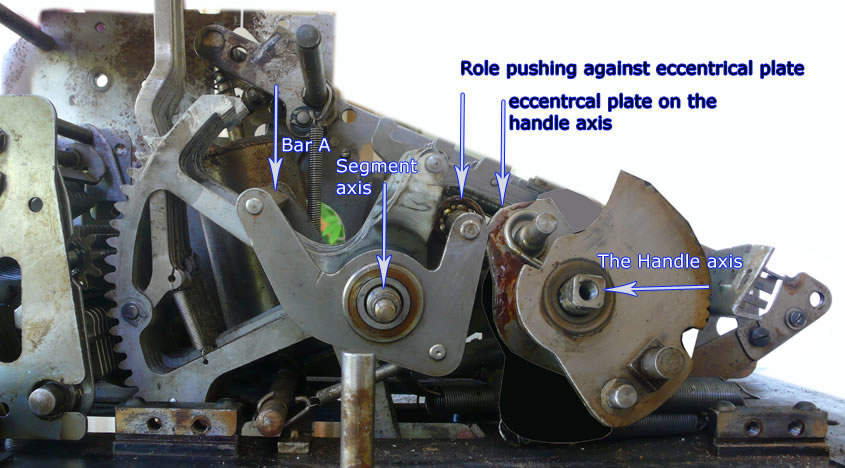

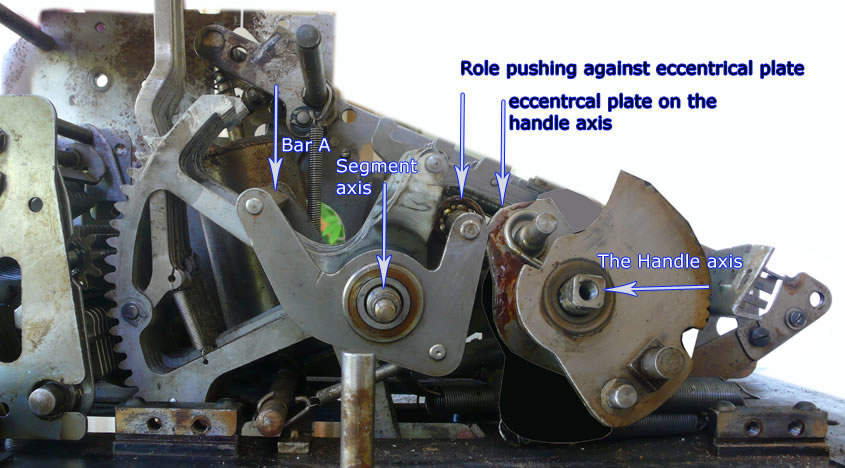

a key is pressed, it will stick out his pin. The activation of the handle, which is on the right main axes, will move the rocking plates to the right. They will follow the bar A which is connected on the second main axis on the left. The segment will be pushed with a middle part of it, against a bar.

Due to the hinged connection the rocking plate will then move to the right. This until a rock of the plate is touching the key-pin of the pressed key. The other segments will still follow the bar A, until they rocking plate meets their pin.

When a nine is pressed the segment is not stopped by the rock plate but turn so far until the axis stopped and the bar A position is then the nine position. This clears the missing nine.

Now the whole sequence again, but with all this knowledge in mind. See photo below. This is the situation of the rest position.

When the handle start to activated, his axis is turning clock wise, the role of the segment axis is following the eccentric plate and turn clock wise as well. Tis will move bar A up. The segments on there turn following bar A. They are drawn against it, until the rock plate below the key board meets a rock of a key pin, the zero clack or the fixed end (the nine) position..

Just before the handle is turning back the gears will be put on the segments. The segments will follow the bar A to the rest position and turn the pinion with the equivalent number of teeth's, according the pressed key's.

A close look to the rocking plate again shows a strange number sequence. A not expected location of the zero after the one.

Why's that done?

Remember there is no zero key, the zero setting is default. When no key is pressed, there is a default clack up, the two digits on the left (on the photo direct to the left).

To the right are three clacks down, as a sign that those digits have pressed keys: 1, 2 and 3. And two clacks are up, those keys not pressed.

So in case no key is pressed that clack is the zero rock for the plate. This rock has a position beyond the 1 position, corresponding with the plates position.

Not a strange position anymore?

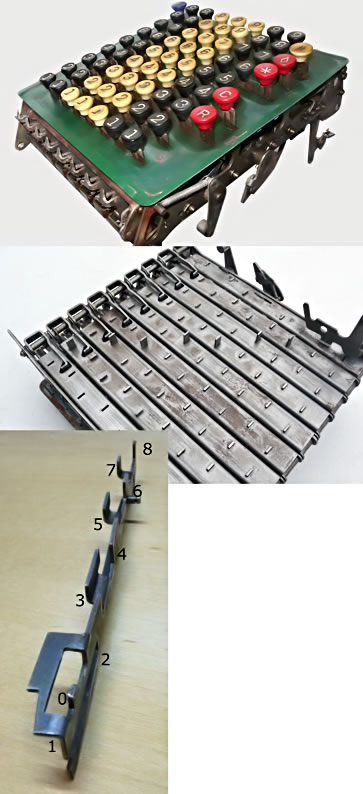

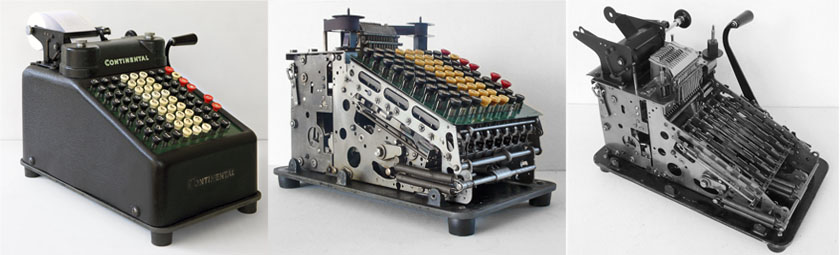

The keyboard and calculating mechanism of the Continental 9

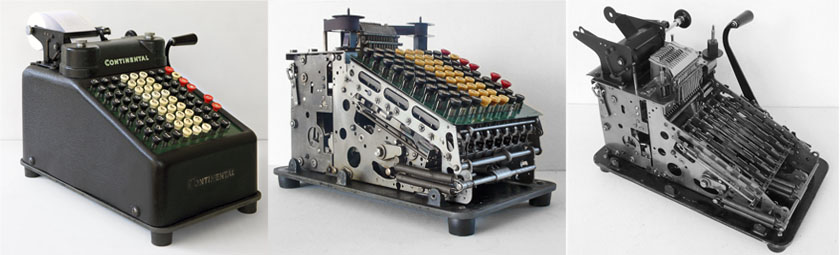

So far the principle, now how it is implemented in the Continental 9 / 9S and in Astra machines. The Continental calculators have the mentioned full keyboards, the Astra machines have the more advanced 10 key mechanism.

The next topics (top side menu) are:

-

keyboard technologies

- tens carry

- ten key key board

-

Multiply

-

Function key's

- animations

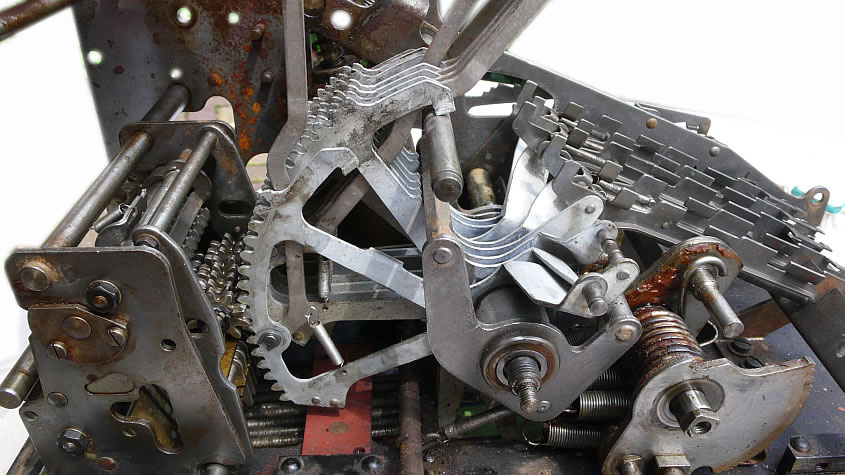

The segment, the printing head and the rocking plates are here separated from the rest. This shows how they are connected.

The three small photo's above: a Continental 9 complete and in two dismantles stages. The large photo above shows the essential parts in more details. On the left hand side of that photo you'll find the calculation unit, with the pinion gears (the register) and the segments. On the right hand side, where the keyboard is removed, we see the key board rocking plates. (A few plates in the front are removed.) Please notice that the gear segments have, on the other side, a hinged connection with the keyboard rocking plate.

Rocking Segment Mechanism (page 1)

Introduction