Below the English names and alternative names, as well as the German names for these technologies:

By the direct add, the value of the key is direct added to the corresponding digit, of the result register. Very fast adding was possible.

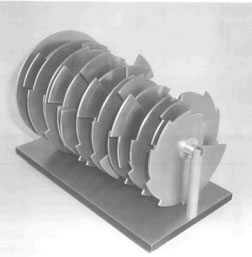

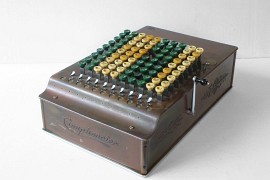

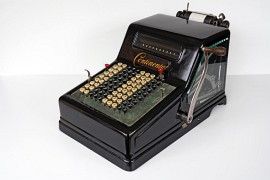

At the Rocking Segment technology, the numbers has to be inputted on the key board, followed by pulling a reciprocating handle. The same for the next numbers. Total or subtotal keys has to pressed and followed by the handle pulling to. That made it successful in the adding and listing and bookkeeping machines. The lowest two technologies of the overview, came from the drawing board of Mr. C. Hamann an Icon in mechanical calculator history. These clever technologies played an important role in calculation automation. In fact the last four technologies have rotating or crank type actuators, which is good for rapid and repeating cycles. That made them suitable for automation. Although it is a sole used technology I like to mention the Marchant Silent Speed Proportional Gears technology used in their Figurematic 8ADX for instance. An other technology used by a few manufacturers, is the Adapting Segment technology, which is used in Marchants LX and H8 machine, the Demos and the EOS.

Further on on this page we will see a one cycle way of multiplication a very interesting method but became no successor.

Beside this subdivision of mechanical calculator technologies, you will find an other qualification, the number of arithmetic functions, which can be performed. This is often used in Germany. The machines, who can easily add or add and subtract only, are called "Ein or Zwei Spiezies Rechenmaschinen" (DL). Machines who could easily perform multiplications or multiplications and divisions as well are called "Drei and Vier Spiezies Rechenmaschinen"(DL) *)2.

So lets combine those two and we will get a performance overview:

| Technology | Can be used for: |

| Direct add | Add, Subtract with nine complement. |

| Rocking Segment | Add and some can Subtract *)1 |

| Pin-wheel | Add, Subtract, Multiply and Divide |

| Stepped drum | Add, Subtract, Multiply and Divide *)2 |

| Proportional Lever | Add, Subtract, Multiply and Divide in a automatic sequence |

| Switching Latch Wheel | Add, Subtract, Multiply and Divide in a automatic sequence |

Concluding observations (How do they calculate, introduction part)

When we have worked ourselves through all these technological details, I think is good to summarize this chapter:

Many people, in previous ages, worked on improving mechanical calculating machines. Those machines displays the results either on printed paper or numbered (0 .. 9) rounds, mounted on the side of gearwheels. One round for every digit. They form the registers of the machine.

The way those gearwheels get turned, for instance during an adding, can be grouped by and are named after, the essential part of the automation / the calculation technology.

We saw that the keyboards and sliders are used for the inputting the figures by hand. These input mechanisms converts a given figure into a corresponding distance or a corresponding number of pins, stick out of a wheel. During the calculation activation, by hand or motor, those keyboard conversions on their turn are converted into equivalent teeth turning of the result gearwheel / register.

We saw that the tens-carry is mostly carried out at mechanisms close to the registers and that machines with a movable carriage are, at the beginning of the mechanical calculator era, the best suitable for multiplication and division.

I like to recommend opening these links:

The last one is on the John Wolff's Web Museum (Melbourne). The complete set-up of the Millionaire.

I like to recommend reading this one, when you think you are good at repairing mechanics. My belief this work is compared to none!! His work was and is still of great help for collectors like I am.

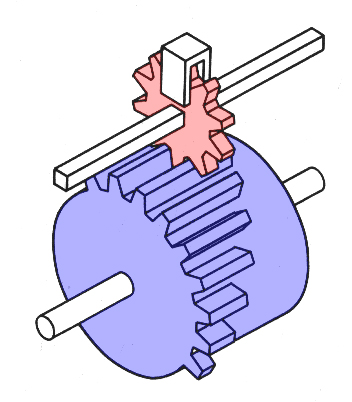

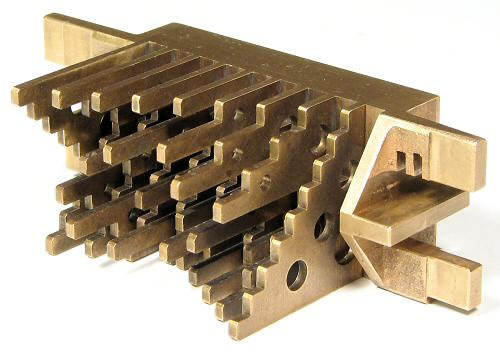

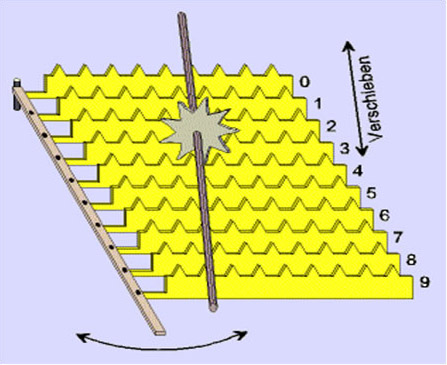

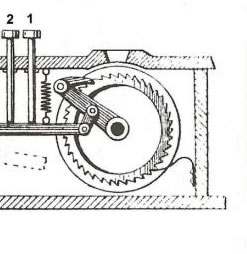

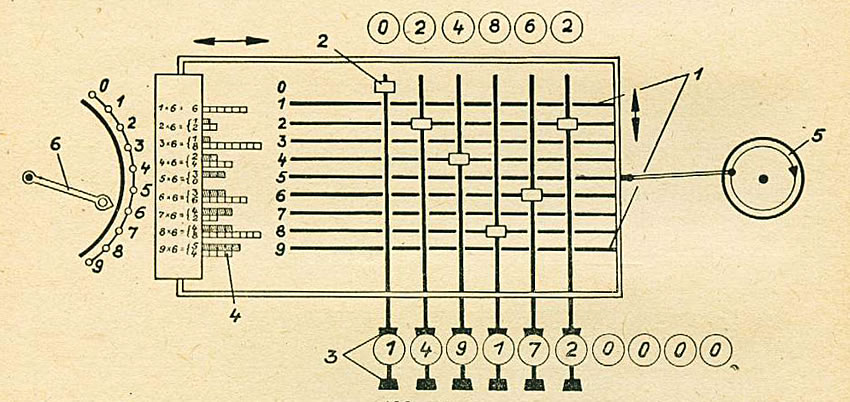

This is the principle of the direct multiplication with a multiplying body (no 4 on the drawing). Instead of only two pins this body has an array of pin sets, where all results of 1x1 till 9x9 are in an row / column configuration. So two pins with the length from 0,1 till 8,1 for each combination / result.

The multiplying body can vertically shifted / tiled to have the exact row (y position of the array) of the multiplier (6 in the drawing above). This by setting the crank no 6. The number to be multiplied (max 8 digits) can be set by sliders no 2. They set the x positions of the multiplying body.

A second turn on the wheel no 5 and a shift of the multiplying body is needed to process the tens carry's, as said this is often more than one unit.(The crank who drives the wheel 5 has a 1 to 2 gear up, so that the crank has only one turn / multiply)

The initial success of the machines was declining due to the:

-

the one digit per machine cycle of one of the multiplying numbers

-

difficult division

-

automats, who came on the market with full automation of multiplication an division.

An other direct multiplication machine was developed by Mr. Moon Hopkins in 1911 in St. Louis. Burroughs marketed this machine under Class 7 in 1921.

The drawing above is taken from the Rechenlexicon / Wittke

1948 Die Rechenmaschine und ihre Rechentechnik

A nice document on the subject is from Ullrich Wolff ( ARITHMEUM in Bonn )

An other pioneer working on direct multiplication was Edmund Barbour (1872) Boston, Massachusetts USA